Commercial, Industrial, Warehouses

High

Insulated

Manual

Motorsied

16000mm (Depending on Height)

5000mm (Depending on Width)

30-40 working days

Folding sliding doors offer a versatile, space-saving solution for various applications, providing excellent heat insulation and storm resistance. They are easy to operate and install, featuring robust and maintenance-free components.

Folding Door FE "Teckentrup 50"

Our folding sliding doors comply with stringent safety and insulation standards, making them suitable for various industrial applications.

Features and benefits:

Size Range

Width - 2250mm - 16000mm

Height - 2000mm - 5000mm

Door Leaf

Made of box-type edged steel sheets with all-round mount for EPDM rubber accident profile (GUP). With top and bottom leaf seal and mounting bracket.

Door Frame

Lateral frame made of rectangular 50 x 90 mm pipe. Top frame profile with guide rail (U-profile) and relief level. Featuring bottom buffer at the bottom.

Special Equipment

Speak to one of our specialist advisors for more information about this product.

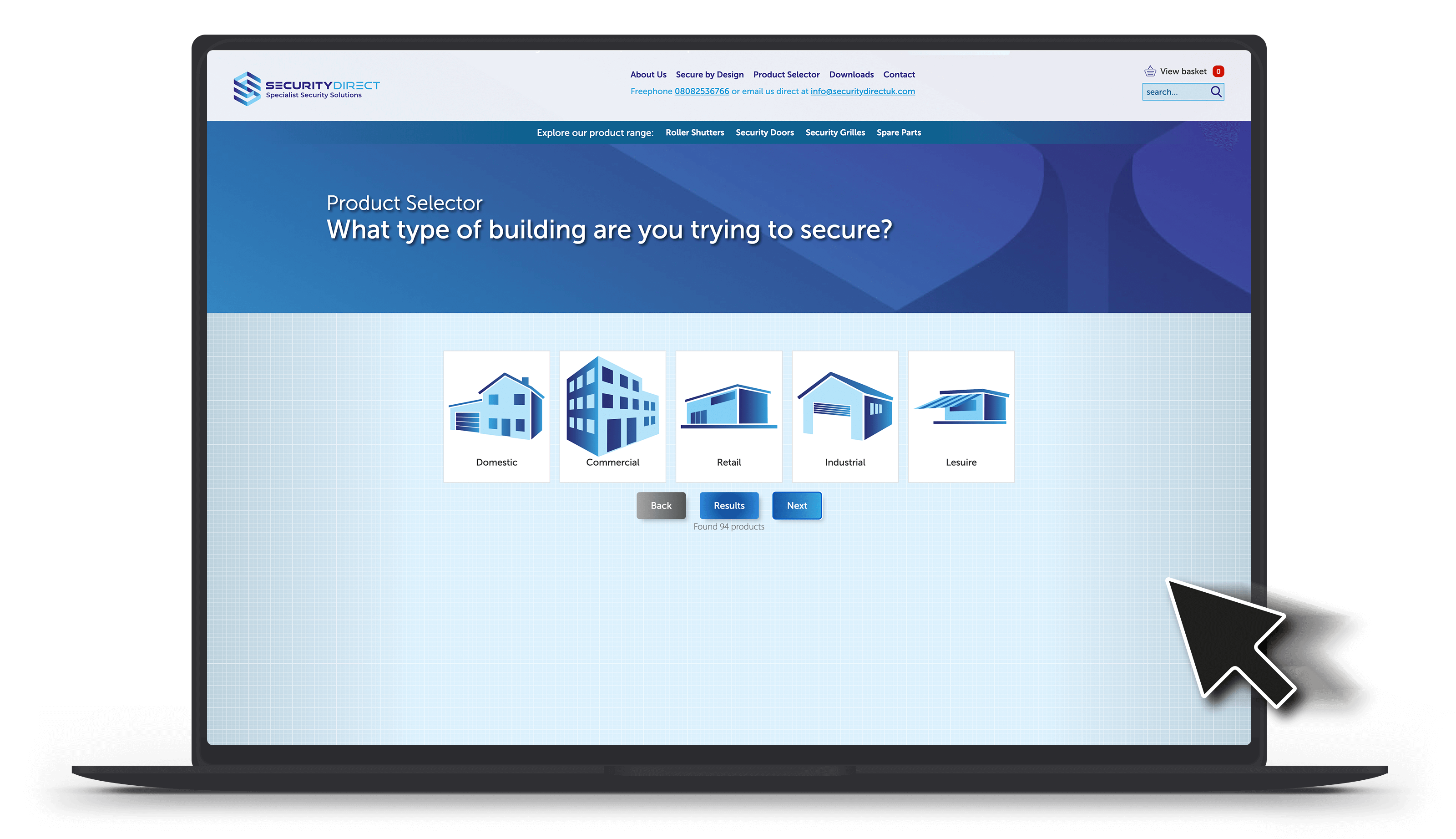

PRODUCT SELECTOR