Roller Shutter Buying Guide

This Security Direct Roller Shutter Buyer’s Guide is designed to help you understand ALL the options available, and with our help, select the right Shutter for your particular application.

LEGISLATION

Roller Shutters are classed as machinery under the Health and Safety at Work Act 1974. They have been known to cause death and injuries, usually from collapsing on people or crushing people, due a lack of safety devices. When purchasing a roller shutter door it is important to take the following into consideration;

CE MARKING

CE marking on a product is a manufacturers and installers declaration that the product complies with the essential requirements of the relevant European health and safety regulations. You would be breaking the Law if you accept a Roller Shutter that has not been properly CE marked.

Manufactures have a responsibility to carry out a risk assessment and make sure the product is safe. Installers have a responsibility to ensure the product is installed as per the manufactures instructions, ensure the door is operating safely and provides operating and maintenance instructions.

For more information on CE marking – CLICK HERE to view the DHF Publication.

MAINTENANCE

Serious accidents and injuries caused by faulty doors are almost always the result of lack of maintenance. If an accident involving an industrial door or shutter takes place, the building manager or owner runs the risk of facing prosecution under the Health Safety at Work Act 1974, for failing to ensure the health, safety, and welfare of his employees. The same legislation also requires employers and the self-employed to safeguard persons not in their employment, which would include visitors, passers-by and even trespassers.

Regular maintenance can also reduce wear and tear on parts, which will increase the life of the product and reduce the risk of breakdowns. Also, by not servicing the door at regular intervals will void any product warranties.

Please speak to our sales team and we can arrange a regular maintenance schedule.

CONCEALING ROLLER SHUTTERS

If you permanently box in or conceal your roller shutter door which prevents access to the roller shutter door for repairs and maintenance, then you are breaking the law, as it is deemed that you have no intention of servicing the door. If the shutter needs repairing, then you will also be looking at expensive building works to remove the boxing in.

PLANNING PERMISSION

Planning Permission maybe required for the installation of roller shutters. This mainly applies to external installations, but it has been known for internal installations on Grade Listed properties. It is the customers responsibility to obtain all consents before the product is installed.

WHAT IS THE ROLLER SHUTTER NEEDED FOR?

Roller Shutters can be fitted over many types of openings, not just doors and windows. The reason why Roller Shutters are installed can be;

VISUAL BARRIER - This could be a Bar Shutter, Servery Shutter or a Shop Front Shutter. This is where cost of the Shutter is more important than the Security it provides.

SECURITY - When the priority is Security then it comes down to Budget. The higher the level of Security the more money you pay for the shutter. We have Shutters that have been tested and certified by the Insurance Companies. Sometimes Insurance Companies may specify a certain security level.

FIRE PROTECTION - This is usually required on Kitchen Serveries and Openings that are located on a Fire Escape Route. A LOCAL Fire Officer or Building Control Officer will specify if a Fire Shutter is required. If you are not sure then I would recommend that you speak to your LOCAL Fire Officer, as Fire Shutters are more expensive than normal roller shutters. They can be wired into a Fire Alarm System and be fully automated OR operated manually by a Switch. Please see our “Fire Shutter Buying Guide” for more information.

WHAT MATERIALS ARE THE ROLLER SHUTTERS MANUFACTURED FROM?

The majority of Roller shutters are manufactured from either Steel or Aluminium. Most people think that Steel is the strongest, but this is not necessarily the case when it comes to Roller Shutters. Steel Laths are usually Single Skin, where are Aluminium Laths are usually Extruded and have a Twin Wall, hence are stronger.

We do get asked about plastic roller shutters, but these are not very common as they are brittle and prone to cracking. Wooden shutters are available, but are very expensive and prone to expanding and cracking. When wooden shutters are preferred we push towards the aluminium roller shutters with a woodgrain finish.

Advantages of Aluminium Shutters:

1) The Guides and Laths are made from an Extrusion process allowing us to build in reinforcements to strengthen the important parts. With Steel Shutters we make the Guides and Laths from flat steel plate and then bend it into shape, hence it is not too difficult to bend it back to break through the shutter. Hence Aluminium is usually more secure than Steel.

2) Insurance Approved for external use whereas we can only get Steel Shutters Insurance Approved for Internal use.

3) Our RA2 & RA4 Aluminium Shutters roll up into a smaller box - 205 mm square, compared to Steel which rolls up into a 300 mm square box. Ideal where there is limited headroom.

4) Aluminium does not rust and so provides better weather and corrosion resistance, so retains its appearance better throughout its life.

5) Powder Coating keys very well onto Aluminium, providing a long lasting finish. Powder Coating onto Galvanised Steel on the other hand does not provide a very good key, hence does deteriorate over time as can be witnessed on many Shop Fronts who tend to go for Steel Shutters being the cheapest option.

6) Aluminium is the preferred solution for Coastal areas because Steel will corrode

7) Aluminium is much quieter and smoother in operation whereas Steel tends to provide more of a “Clanking” sound.

Advantages of Steel Shutters:

1) Usually the lowest cost option

2) Aluminium will only go up to 6 metres wide and 5 metres high, whereas Steel is available for sizes up to 7 metres wide and 7 metres high.

TYPES OF CURTAIN AVAILABLE

There are basically THREE types of Curtain Lath available. On some shutters we can mix TWO types of Lath together in the same shutter curtain e.g some Punched Laths at eye level for Vision with the

remainder of the curtain Solid Laths.

SOLID LATHS - Solid Laths are solid, you can’t see through them and are usually the cheapest type of Lath. Solid Laths are also more secure than Vision laths.

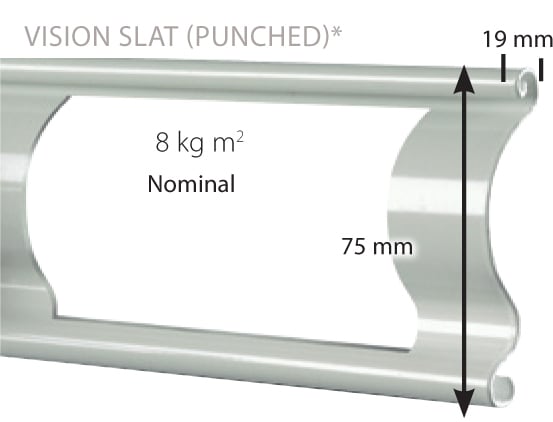

PERFORATED LATHS - These are small holes that are punched into the Laths. They give usually around 15 % Vision.

PUNCHED LATHS - These are best described as Grille Type, Slotted or Letterbox Cut Outs. Depending on which type of Lath, provides between 44 and 69% Vision. On some of these laths you can get your hands through, so the option of either smaller spacing or polycarbonate inserts are also available.

GRILLE TYPE - These are described as PortCullis type roller shutters. They normally provide more vision that punched slat, but are generally not as secure.

TYPES OF GUIDE RAIL AVAILABLE

1) Standard Fixed – for Normal Security applications

2) Heavy Duty Fixed – for High Security applications - as little as £27 + VAT per Shutter. Available on our RA2 & RA4 Shutters – wind end locks will be fitted to the curtain as standard

3) Removable Type – for Bar and Servery applications with 2 Shutters coming together and where the opening needs to be kept clear.

TYPES OF OPERATION

There are Two Types of Operation - Manual Operation and Electric Operation. When trying to

decide, ask the following Health and Safety questions;

Who is going to be operating the Shutter?

What are their Physical abilities?

Can they operate the Shutter without leaning or stretching across anything?

TYPES OF MANUAL OPERATION

Tape Winder - With the shutters fitted externally there is a Grey Cord that comes through the wall to the inside, that you pull up and down to operate the shutter. Available on the RA2 & RA4 but we don’t recommend this type of operation as it’s prone to faults and is not secure.

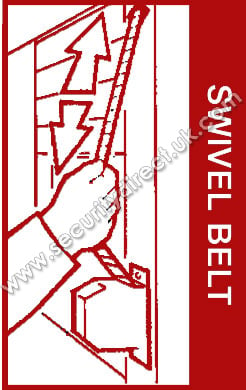

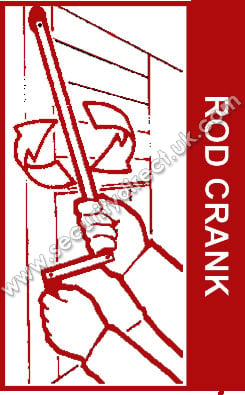

Rod Crank - This is a winding handle that you turn to open and close the shutter. We don’t recommend this as it’s slow to operate and not very secure but better than the Taper Winder.

Chain Operated - This is an old fashioned way to operate large industrial roller shutters. This has become less common as Electric operation on larger shutters is cheaper than Chain operation.

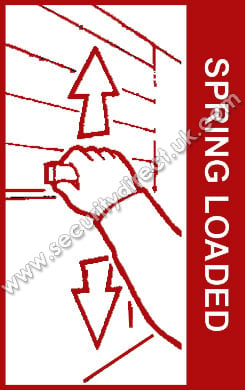

Spring & Lock - This is the most popular type of Manual Operation. You simply Lift Up and Pull Down the Shutter – with a Spring Assist. It is locked using a central Lock in the Bottom Lath, you turn the key and TWO Bolts Shoot outwards to lock into the guide rails at each side.

ELECTRIC OPERATION

This involves a Motor that powers the Roller Shutter. On Domestic and Commercial Shutters we use a Tubular Motor that fits inside the barrel at one end and works off normal 240 Volt single phase electrical supply. We use Top Quality motors than come with a 5 year’s parts Warranty. There are cheap Chinese motors on the market but we never use these.

With the larger Roller Shutters we can use 3 Phase (415Volt) Motors. These motors are usually fitted on the side of the shutters and have a chain override as standard. These 3 Phase Industrial Motors are used on large doors, high usage or High Speed doors.

We would normally recommend any shutter that is over 2000mm Wide and 2100mm High to be Electric Operation. We can supply Manually Operated Shutters bigger than this if required. The reason we recommend Electric operation is to comply with the Health and Safety Executive “Safe Lifting Loads”. When deciding on the operation, we suggest you think who is going to be operating the shutter and whether or not they have to stretch across to operate the shutter.

Electrically Operated Shutters are not much more expensive than Manual Operation. On normal shutters it can be as little as £100 difference. What makes Electric operation expensive is when you introduce sophisticated control systems i.e; Remote Control Systems and Battery Backups.

CONTROLS FOR ELECTRIC SHUTTERS

HOLD TO RUN - The standard control for an Electric Roller Shutter is a "Hold to Run" switch. You must keep your finger pressed to open or close the roller shutter. As soon as remove your finger from the switch, the shutter will stop. When you have a Hold to Run switch in sight of the roller shutter, you dont need safety devices fitted.

REMOTE CONTROL - Remote Control is a receiver fitted to the wall, which the shutter connects into. A hand transmitter is then used to Open and Close the roller shutter. For safety reasons, safety devices must be fitted to the roller shutter when using remote control operation. Usually this is a Rubber Safety Edge, so if it hits anything when closing the shutter will auto stop.

SENSORS - On industrial Doors and Car Parks we can install a range of sensors that automatically detect presence ie; Vehicles or Pedestrians and the shutter automatically opens. This is very popular on warehouse doors, where Fork Lifts are going are regularly going in and out of the doors.

SAFETY DEVICES

The law states that if cannot see the roller shutter from the switch location, then safety devices must be fitted. Depending on the risk, will depend on the safety devices installed. For a roller garage door, remote control operation, we install a safety edge which is a rubber strip that runs along the bottom of the curtain. If the rubber hits something, it compresses and the shutter stops. For high usage applications for example Warehouse Doors, we can fit a rage of sensors that provide a non contact safety. The sensors will detect the presence of an object within a zone near the shutter and will prevent the door from closing. Some of the sensors like the Widescan sensor, provide different zones in front of the shutter for Motion, Presence and Safety.

With a large range of Roller Garage Doors, it can be confusing to see what the differences are between the different models.

Sometime you may get a power failure and still need to open or secure the roller shutter. If this is the case then you need to consider a Manual Override. We have Two types of Manual Overrides;

Winding Handle - A separate winding handle with a Hex Bar attachment is slotted into the motor end of the shutter box and connects into the motor drive. You then simply wind the shutter open or closed. This can be a fiddly, depending on where the hole for the override is located and if you have the winding handle available. Also winding the handle can be a slow process. However, for the very occasional time that it may be required, could save a lot of time, cost and aggravation. So well worth paying the extra £45 + VAT but also specify a Manual Override Lock at an extra £24 + VAT to prevent other people being able to override your Shutter.

Battery Backup Unit - This is a Large Battery than is constantly plugged into the power source.

The shutter is then wired through the Battery Backup. If the Power fails, the shutter draws its

power from the Battery. The batteries are only designed to give 5-8 operating cycles. These are a

more expensive options ranging from £200 - £600 + VAT depending on the size of the shutter.

WHAT FINISHES ARE AVAILABLE?

Industrial Steel Shutters come in a Galvanised finish only as standard whereas Commercial Steel Shutters, as standard, can be either Powder Coated one of our FIVE Standard Colours OR left in Galvanised finish.

Aluminium Roller Shutters are Powder Coated as standard in one of our FIVE Standard Colours. We cannot supply the Aluminium shutters in the natural mill finish.

On top of the FIVE Standard Colours, we have an additional range of SIXTY SEVEN colours in stock.

Our quotations detail the extra costs for each of these colours. The full range of colours can be seen on our website. If we don’t have the colour in stock, then we can buy it in especially at an extra